Food Additive SilicaOvercoming the Dilemma of Powder Ingredients

Nowadays, convenient and fast foods are becoming more and more popular. Powder ingredients are often used in food formulations due to their quick and instant dissolving properties. Since most of the powder particles are fine and easy to stick, and the powder particles have poor fluidity and are easy to agglomerate during storage, it is difficult to operate and correctly add materials, especially for materials that are prone to moisture, such as fruit powder and vegetable powder. , Flavors and spices, chili powder, etc.

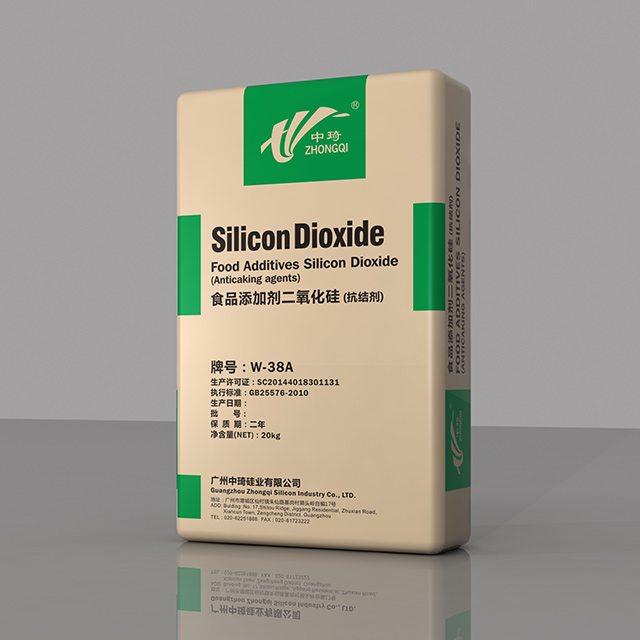

The emergence of food additive silica has solved this problem. Silica is a new green, safe and healthy food additive. It has excellent physiological inertness, chemical stability, high fluidity, and high adsorption. It accumulates in the body, which makes silica a rising star in food additives.